Navigating the intricate world of mathematical modeling can often feel like traversing a labyrinth, especially when confronting complex mechanical systems with numerous degrees of freedom, such as a wind turbine gearbox. In such endeavors, the 𝐋𝐚𝐠𝐫𝐚𝐧𝐠𝐞 𝐦𝐞𝐭𝐡𝐨𝐝 stands out as a common approach, offering a structured framework for capturing the system’s dynamics.

Yet, amidst the elegance of mathematical formalism, lies a lurking challenge — the susceptibility to human error. Despite our best efforts, the intricacies of model development can sometimes lead to inaccuracies, inconsistencies, or oversights that compromise the integrity of the results.

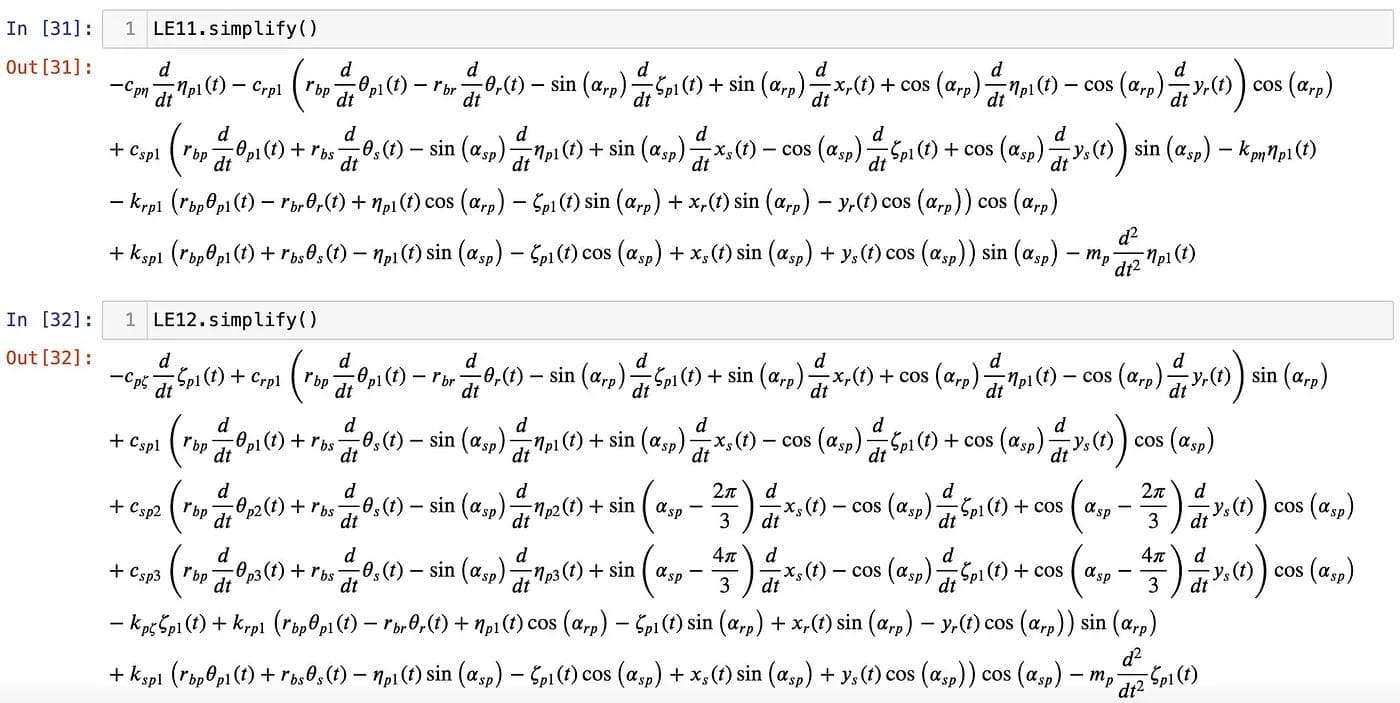

This is where innovation steps in to bridge the gap between theory and application. Recently, I embarked on a journey to enhance the modeling process by harnessing the power of automation. Through the development of 𝐏𝐲𝐭𝐡𝐨𝐧 code utilizing the symbolic 𝐏𝐲𝐭𝐡𝐨𝐧 library, I’ve unlocked the capability to automatically generate dynamic equations.

By seamlessly integrating automation into the modeling workflow, we not only expedite the prototyping phase but also mitigate the inherent risks associated with human error. Imagine a process where equations materialize effortlessly, free from the constraints of manual derivation, allowing for a more robust and reliable modeling process.

Moreover, this approach extends beyond equation generation. With the obtained dynamic equations readily available within the 𝐏𝐲𝐭𝐡𝐨𝐧 environment, we can seamlessly transition to solving and analyzing the system’s behavior, further streamlining the entire modeling pipeline.

As we navigate the ever-evolving landscape of mechanical engineering and mathematical modeling, let us embrace the possibilities that automation presents. Together, let’s redefine the boundaries of what’s achievable and pave the way for a future where precision and efficiency converge seamlessly.